- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-02-17 Origin: Site

The performance of fuel lines depends largely on their material, which must withstand pressure, temperature fluctuations, and chemical exposure from fuels. The right material can mean the difference between reliable operation and frequent system failures, so understanding the properties of each option is key to making an informed choice. Whether you need a flexible rubber hose, a high-pressure braided fuel line, or a chemical-resistant PTFE fuel line offers tailored solutions for every need.

1.1 Rubber Fuel Lines: Versatile & Cost-Effective

Rubber hose is the most common material for fuel lines due to its flexibility, ease of installation, and affordability. It balances performance and practicality, making it suitable for a wide range of standard applications where extreme conditions are not a concern. stdrubberhose’s rubber fuel lines are engineered for reliability in both standard and moderately demanding environments:

• Products: SAE J30 R6/R10 series SAE J30 R10 Hydraulic Rubber Fuel Hose in Tank/SAE J30 R6 High Pressure Textile Braid Hydraulic FuelHose

○ Properties: Oil-resistant, weather-resistant, and flexible, with textile braid reinforcement for added strength (braid hydraulic fuel hose variants). These properties make it easy to route around obstacles and compatible with most standard fuel types.

○ Applications: Conventional fuel systems, return lines, commercial vehicles, agricultural equipment, and construction machinery.

○ Custom Options:

▪ Sizes: Inner diameter from 3.2mm (1/8") to 25.4mm (1"), including 3/8 fuel line hose.

▪ Pressure: Standard 20-35bar, with medium-pressure upgrades available for more demanding setups.

▪ Connections: Compatible with clamps, quick-connect fittings, and custom adapters to match existing systems.

○ Key Advantage: Cost-effective for bulk orders, resistant to vibration, and suitable for most standard fuel types—making it a versatile choice for everyday applications.

1.2 PTFE Fuel Lines: Extreme Performance & Chemical Resistance

For extreme conditions where rubber hoses may degrade, PTFE fuel line is the ideal solution. PTFE (polytetrafluoroethylene) offers superior chemical resistance, high-temperature tolerance, and leak-proof performance, making it suitable for specialized and high-stakes applications.

• Product: PTFE SAE100 R14 Wire Braided Hydraulic Rubber Hose

○ Properties: PTFE lining (inert to most chemicals), stainless steel wire braid reinforcement (for high pressure), and temperature resistance from -54℃ to +204℃. This combination ensures stability even in extreme heat, cold, or corrosive environments.

○ Applications: Extreme-temperature environments, corrosive fuel transfer (e.g., synthetic fuels, ethanol blends), marine fuel lines, and industrial machinery. It is particularly well-suited for systems where fuel purity and leak prevention are critical.

○ Custom Options:

▪ Length: 1-100 meters, no joint splicing for long runs to minimize leak points.

▪ Pressure: Up to 275bar (4000psi) for high-pressure systems that require maximum durability.

▪ Outer Layer: Stainless steel or nylon fuel line braid for added protection against abrasion and physical damage.

○ Key Advantage: Prevents fuel permeation, lasts longer than rubber in harsh conditions.

1.3 Braided Fuel Lines: Strength & Durability

Braided fuel line (including textile and wire braid variants) combines the flexibility of rubber with enhanced strength, making it suitable for high-pressure and high-vibration applications. The braid reinforcement adds tensile strength and pressure resistance, while the inner tube (rubber or PTFE) ensures compatibility with fuels. stdrubberhose offers two popular braided options:

• Products: SAE 100 R3 (textile braid) and SAE 100 R14 (wire braid)

○ Properties: Braid reinforcement adds tensile strength and pressure resistance, while the inner tube (rubber or PTFE) ensures fuel compatibility. This design resists kinking and bursting, even in high-stress environments.

○ Applications: High-pressure fuel injection systems, hydraulic fuel lines, commercial vehicles, and marine equipment. The 3/8 fuel line hose braided variant is popular for performance vehicles and industrial machinery where reliability under load is essential.

○ Custom Options:

▪ Braid Material: Textile (for medium pressure) or stainless steel wire (for high pressure) to match specific pressure requirements.

▪ Colours: Custom outer layer colours for easy identification in complex systems, reducing installation and maintenance time.

▪ Sizes: From 6mm to 50mm inner diamete.

While standard fuel lines work for most applications, non-standard setups or specialized environments often require custom solutions. stdrubberhose specializes in tailoring fuel line hose products to address unique needs, ensuring a perfect fit and optimal performance. Common custom requests include:

• Non-Standard Sizes: Custom inner/outer diameters and lengths for tight spaces or specialized equipment where standard sizes cannot be used.

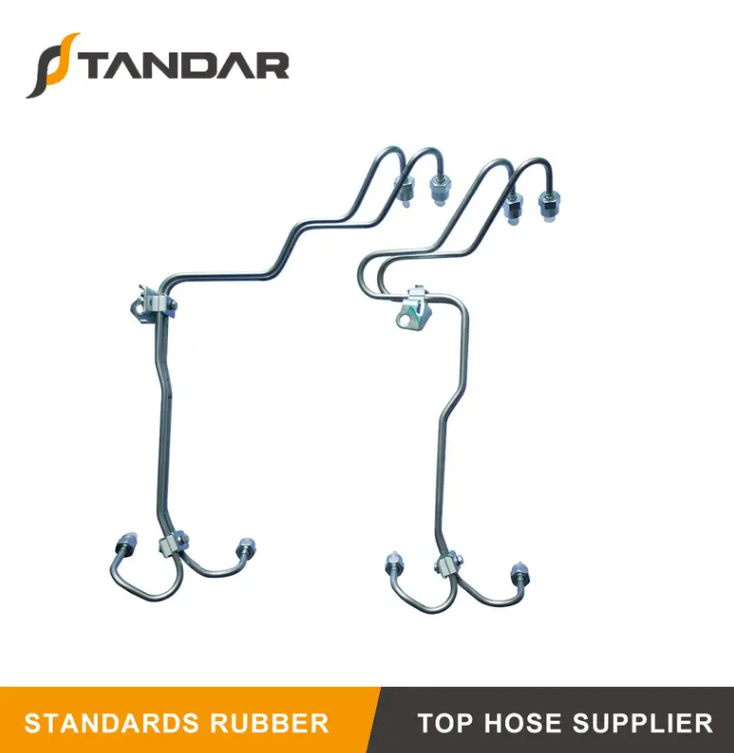

• OEM Matching: Custom fuel lines based on OEM part numbers (e.g.,4059312, 2874410) for Cummins engines vehicles , ensuring compatibility with existing systems.

• Extreme Environment Adaptations: Custom materials for high-temperature (+200℃+), low-temperature (-50℃-), or corrosive environments (e.g., marine fuel line exposed to seawater) where standard materials would fail.

• Specialized Connections: Custom fuel line fittings, or quick-connect adapters to match existing systems, eliminating the need for costly modifications.

1. Consultation: Share your requirements (size, pressure, temperature, fuel type, application) with stdrubberhose’s technical team. They will provide expert advice to ensure the solution meets your needs and complies with relevant standards.

2. Design & Quotation: Receive a tailored solution and quotation, including material recommendations, technical drawings, and lead time. This step ensures transparency and allows for adjustments before production begins.

3. Sample Testing: Request a free sample to verify fitment and performance before bulk production. This step gives you confidence that the custom product will work as intended.

4. Production & Delivery: Bulk production begins after sample approval, with fast delivery (10-25 days for custom orders). stdrubberhose uses high-quality materials and strict quality control to ensure consistency and reliability.

5. After-Sales Support: Troubleshooting, and replacement parts.