- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

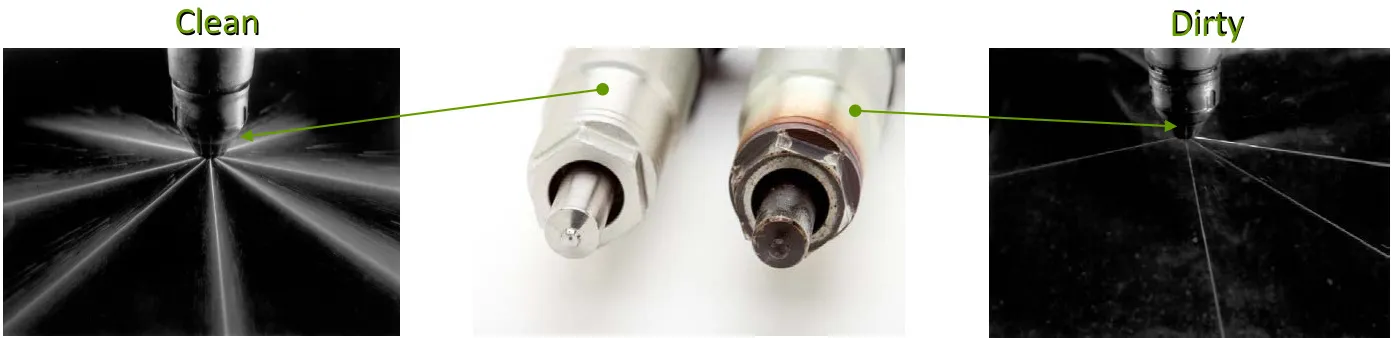

If your diesel engine is suffering from rough idling, reduced fuel efficiency, or excessive smoke,dirty fuel injectors are likely the cause. Over time, fuel impurities and carbon deposits accumulate in common rail diesel fuel injector , disrupting spray patterns and precision fuel delivery. Regularly cleaning fuel injectors can restore engine performance—and you can complete the task yourself with the right tools and steps.

Before starting the cleaning process, confirm your injectors actually need attention. Common warning signs include:

• Engine misfires or uneven running

• Decreased fuel economy (more frequent refuelling stops)

• Difficulty starting, particularly in cold weather

• Excessive exhaust smoke (black or grey)

• Poor acceleration or loss of power

These issues often originate from clogged nozzles or carbon buildup in high-pressure common rail fuel injectors—a common problem in commercial vehicles, trucks, and engineering machinery. Recognising these signs early can prevent further engine damage.

To carry out effective cleaning, you’ll need:

• A fuel injector cleaning kit (ensure it’s compatible with diesel systems)

• Diesel-specific fuel system cleaner additive

• Basic hand tools (screwdrivers, wrenches)

• Safety gear (gloves and goggles)

For heavy-duty engines (such as those in Cummins-powered trucks), select a kit designed for high-pressure injectors to avoid component damage. Using the correct tools is crucial for achieving thorough cleaning without harming your injectors.

Follow these steps to clean your injectors safely and efficiently:

1. Prepare the engine: Turn off the vehicle and disconnect the battery. Locate the fuel injectors—they are typically attached to the fuel rail on top of the engine.

2. Add fuel system cleaner: Pour a diesel-specific cleaning additive into the fuel tank. This softens mild deposits before deep cleaning.

3. Connect the cleaning kit: Follow the kit instructions to attach it to the fuel rail, bypassing the fuel tank. Use the kit’s specialised cleaning solution, formulated to dissolve carbon deposits without corroding parts.

4. Run the cleaning cycle: Start the engine and let it idle for 15–20 minutes. The cleaning solution will circulate through the injectors, removing clogs and restoring optimal spray patterns.

5. Test the engine: After cleaning, disconnect the kit, reconnect the fuel tank, and start the engine. Check for smoother idling and improved acceleration—key indicators of successful cleaning.

While cleaning works for mild deposits, it won’t fix worn, leaking, or high-mileage injectors. Use the table below to decide whether to clean or replace your injectors:

Scenario | Clean or Replace? | Key Notes |

Mild deposits, engine has <100,000 km | Clean | DIY or professional cleaning will suffice |

Persistent misfires after cleaning | Replace | Indicates underlying wear or damage |

Leaking nozzles (visible fuel drips) | Replace | Leaks lead to inefficient fuel use and safety risks |

Failed spray pattern tests | Replace | Uneven fuel distribution harms engine performance |

Injectors have >150,000 km | Replace | Manufacturer recommendations advise replacement for optimal reliability |

For reliable replacements, choose Standards Rubber’s OEM-quality common rail diesel fuel injectors. Our 0445110 series (compatible with Bosch, Volvo, and Cat engines) and Delphi 33800 series undergo strict outbound inspections to ensure flawless performance. With complete models in stock and easy installation, they are the ideal solution for repair shops and fleet managers.

Cleaning fuel injectors is a simple way to extend engine life, but quality replacement parts are essential when cleaning isn’t enough. Explore Shijiazhuang Standards Rubber Products Co.,Ltd full range of diesel fuel injectors for trucks, agricultural equipment, and engineering machinery—backed by worry-free after-sales service.

If you are interested in any of the above components or need a complete fuelinjection system that complies with SAE J200/CA510/AII 510 standards, please contact us for technical data, quotations, or samples.

• Email: sales@stdrubberhose.com

• Phone: +86 15373831907

• Online Form: Visit https://www.stdrubberhose.com/contact.html and submit your requirements; we will reply within 24 hours.